A Broad Chocolate History Timeline Emphasizing Key Events

May 23, 2022

Truly Ethical Chocolate Bars and Brands Worth Your Money – UK

December 5, 2022What is Bean to Bar Chocolate?

True meaning, history, and process

Bean to bar chocolate is more than just a label. It is a movement championed by small-batch chocolate makers

What is bean to bar chocolate? Just a chocolate-making process? Absolutely no.

One would say every chocolate bar is bean to bar because chocolate comes from the cacao bean, which is the seed of the Theobroma cacao tree. But every chocolate bar is not the same thing!

And I’m not just talking about the differences in percentages of cacao solids in each product, but the differences in product quality, how and where the beans were processed, their region of origin, and the profitability of the supply chain to the farmer.

In the chocolate industry vocabulary, you may come across terms like industrial chocolate, tree-to-bar chocolate, bean-to-bar chocolate, craft chocolate, or even seed-to-bar chocolate.

These are not legal definitions, but they carry nuances that are important for the chocolate consumer who cares about the sustainability of the cacao supply chain and the future of the chocolate industry.

With that said, let’s see the true meaning of bean to bar chocolate

What is Bean to Bar Chocolate?

Bean to bar chocolate is chocolate made from the whole bean by the same manufacturer. This is different from chocolate produced from cocoa mass or cocoa powder from beans processed by a different company.

Sounds pretty straightforward, right? But it doesn’t let you in on the history of the bean-to-bar label and the values espoused by the small-batch or craft chocolate movement.

The History of Bean to Bar Chocolate

The bean to bar chocolate movement started in the 1990s and spread in the 2000s and 2010s. Around 2005, the label “bean to bar” was used to distinguish small batch chocolates from industrial chocolate. The label has since adopted the image of a business model with larger companies also using it on some of their product lines.

As such, a label might not truly identify with the values and culture of the original movement. That’s why some small-batch chocolate makers prefer the label “Craft Chocolate” instead.

In essence, a true bean to bar chocolate maker values quality over quantity, engages in transparent buying practices like equitable bean prices for the farmer, and controls the origin of their cacao beans

Why is Bean to Bar Chocolate Better?

How is Bean to Bar Chocolate Made?

The bean-to-bar chocolate making process is no different from the general chocolate bar making process except in the differences around the control of entire process, quality, provenance, and fair trade.

Below are the steps on chocolate bar making process, from the cacao pod on the tree to the final bar that melts on your tongue.

1. Cultivation

Theobroma cacao is a plant that grows in the tropics within 20 degrees N and S of the equator. Depending on the varietal, a new plant takes around 3 years to begin to develop flowers on the trunk and branches, and about 5 years to produce significant fruits called pods. After successful pollination, a pod develops, grows, and ripens in about six months. Meanwhile, the farmer grooms the tree by providing the right atmosphere for photosynthesis, spraying pesticides, and using fertilizers when necessary.

2. Harvesting

Ripe cacao pods do not fall off from the tree like other fruits such as mangoes. So the farmer has to know when they are ripe and then harvest them with machetes or special knives, careful to avoid damaging the flowers on the trunk. Since pods ripen throughout the year, harvesting also goes on throughout the year.

The harvested pod is sliced open to remove their seeds. Depending on the variety, a pod can hold around 20-60 cacao beans covered in sweet white pulp. The bean inside is very bitter and acidic.

What happens in the next stages determines largely the quality and flavor of the final product.

The chocolate industry values the bean more than anything else from the cacao plant. As a result, the pulp surrounding the bean is usually wasted during fermentation. Here at Bantu Chocolate, we make sure nothing waste! After removing the beans from the pods, we take out the pulp to make a healthy Cacao Pulp Juice leaving just enough pulp on the bean to aid fermentation.

3. Fermentation

The pulp-covered seeds are put into sweatboxes or laid on the ground and covered up to ferment for 2-7 days depending on the cacao variety. High temperatures and high sugar content in the pulp help yeast to break down the sugar into alcohol while good bacteria convert alcohol into ascetic acid. The cotyledons in the beans die and release the polyphenols in them in a process that begins the development of chocolate flavor while reducing the bitterness in the bean.

4. Drying

The fermented beans must be dried, either in the sun or artificially, to reduce its moisture to about 7%. When done right, avoiding slow or rapid drying, this prevents mold formation during storage and transportation, enhances the bean’s chocolate brown color, and reduces its bitterness and acidity.

Dried beans are transported to the chocolate manufacturing unit where they’re cleaned of foreign particles. Then the beans are ready for the next crucial stage.

5. Roasting

Roasting augments the flavor development that was initiated by the last stages and kills any microbial contaminants from the drying stage. With the bean subjected to high temperatures, the characteristic chocolate brown color of the beans deepens.

6. Winnowing

Roasted beans are cracked in a machine to separate the nibs (cotyledons) from their shells (husks). From there, the nibs and shells journey to the winnower where the shells are blown out, leaving the nibs ready for the next stage.

7. Grinding

Roasted nibs are ground into a thick liquid called cocoa mass or cocoa liquor, which by the way contains no alcohol.

If chocolate was not the final product, cocoa mass would be pressed to remove cocoa butter, and the resultant cocoa cake pulverized into cocoa powder.

8. Conching

Cocoa mass is mixed with sugar and other ingredients to form chocolate. Conching is the process that further improves on the chocolate flavor and texture by having kneaders run back and forth in the chocolate until all cocoa solids are finely ground and coated by cocoa fat.

9. Tempering

This is a heating, cooling, and reheating process which results in a glossy chocolate bar that breaks with a distinct snap and melts smoothly in the mouth.

Why You Should Care About Fair-Trade Certified Bean to Bar Chocolate

Besides the tastier high-quality products you get to savor, eating fair-trade certified chocolate has a ripple effect that should make you really proud of your choice of brands or products as a consumer.

Farmers need better remuneration for their labour so they can live above the poverty line. The average farmer currently makes less than $2 per day from cacao-related activities. To increase yields, they enlarge their farmland by destroying forests and use child labour to reduce cost of production.

Better prices will sustain cocoa farming, eliminate forest destruction, and send children to school instead of the farm to work with dangerous tools.

Without a sustainable supply chain, the future of chocolate might as well be uncertain because the younger generation of farmers in cacao-producing countries have little incentive to get involved in cacao production.

Fair trade chocolate makers are not after high profits. Instead, we seek an equitable value chain that benefits farmers and their communities, the environment, the consumer, as it does the manufacturer.

Bantu Chocolate, especially, uses empowerment instead of charity to empower our community in Cameroon. When you buy our expensive chocolate bar or cacao pulp juice, you become part of those helping to empower our community and contributing to a better future.

See how we can cultivate a better future together

London-based Bean to Bar Chocolate Makers in the UK

Based in the UK, we have a circle of fellow bean to bar chocolate makers here that we trust to give you a great chocolatey experience. As mentioned in the introduction, bean to bar is not just a marketing label about the chocolate making process, but it is also about the stories that drive the craft chocolate maker. Click to learn about our artisan friends.

Bantu Chocolate is a UK-based bean-to-bar chocolate maker, and we’re unique in several ways:

We’re actually a tree-to-bar chocolate maker. We don’t only know the origin of our cacao beans, but we grow our own cacao on our own land in Cameroon! Therefore, we have complete control over the quality of our product from the farm, through fermentation, to processing of the cacao beans.

We’re vegan–friendly. No dairy ingredients in our products, so any and everyone can consume our chocolate bars and cacao pulp juice

We ensure sustainable and eco-friendly cocoa farming. Forest destruction is a major problem in the cacao industry with large acres of rain forest being cut down to make land for more cacao tree planting. By promoting agroforestry and biodiversity on our farm, we conserve the home of wildlife and protect our planet from the damaging effects of climate change.

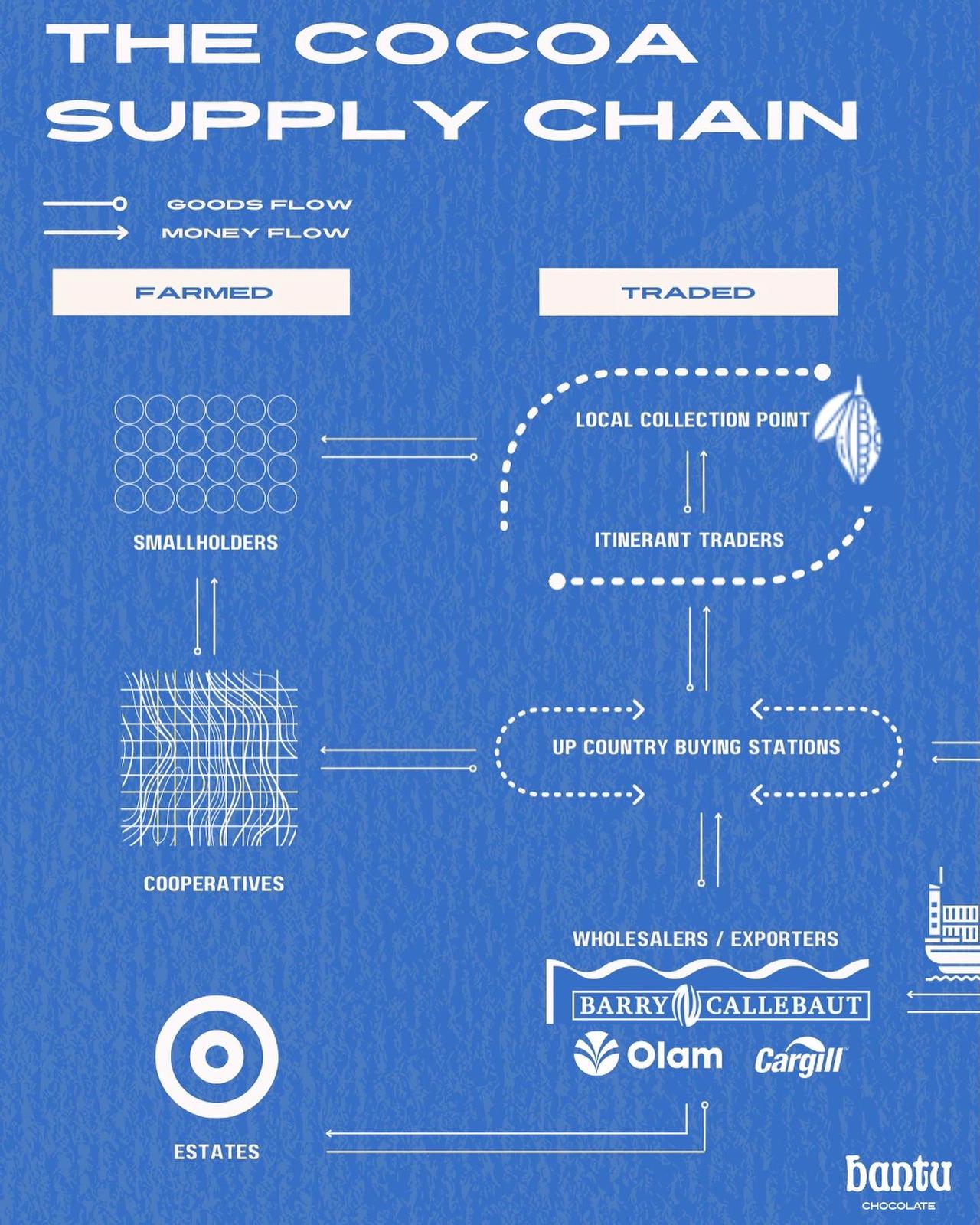

We provide a living income for our workers. Our slogan says, “Beyond Fair Trade”, and that’s not just for fancy. Africa produces more than 70% of the world’s cacao beans, but poverty is the norm for the average farmer. This is because the supply chain is dominated by large corporations, and certifications like Fair Trade have not helped to take the cacao farmer above the poverty line. As farmers of our own cacao, we shorten the supply chain, cutting out what should have gone to middlemen and large cacao bean distributors. When you buy our chocolate bar or cacao pulp juice, you’re helping us help our workers in Cameroon get a decent life for their vital role in the chocolate supply chain.

References:

Chocolate Crisis: Climate Change and Other Threats to the Future of Cacao, by Dale Walters

www.barandcocao.com

Cacao Bean to Bar, a cacao grower’s manual, by Pacita U. Juan, Josephine V. Ramos, Ma. Regina S. Francisco

Chocolate Extinction: Fact vs. Fiction + What Chocolate Lovers Can Do

Chocolate ExtinctionFact vs. Fiction, What Consumers Can Do Share On Facebook Twitter Email Is the world really running out of chocolate? Not really. Currently the global […]

Corporate Chocolate Gifting Ideas to Appreciate Employees and Delight Clients

Corporate Chocolate GiftingHow to Appreciate Employees & Delight Clients Share On Facebook Twitter Email When it comes to corporate gifting, a one-gift-fits-all approach just doesn't cut […]

Cacao Supper Club at Home: Guide to Tasting Chocolate, Cacao Tea, and Pulp Juice

Cacao Supper Club at HomeGuide to Tasting Chocolate, Cacao Tea, and Pulp Juice Share On Facebook Twitter Email Imagine gathering around the table with a few […]