Beverage Adaptogens vs. Caffeine: Which is Good for You?

May 6, 2024

Pets and Chocolate: Vets Say White Chocolate is Unlikely to Poison

June 1, 2024Tree to Bar Chocolate

How Our Ethical Model Benefits Farm Workers, the Environment and the Consumer

Our decision to make tree to bar chocolate is not primarily to have control over product quality and flavour development although that’s very important to every craft chocolate maker.

Our motivation lies in creating a fair, sustainable supply chain that benefits both cocoa farm workers, our farming community, and ethical consumers. We’re proud to craft quality slave-free, single-origin chocolate from farm in Cameroon to London, shipping across the UK, US, and Canada.

In this article, we show you our unique approach to tree to bar chocolate and why we’re more than just tree to bar chocolate makers.

What is tree to bar chocolate?

Because tree-to-bar is not a legal term, there are different takes to what makes for tree to bar chocolate. For some, it could mean that a chocolate maker, usually in the UK, US, Belgium, or somewhere in the West, has a direct relationship with cacao farmers in cacao-producing countries in West Africa, South America, or elsewhere. This direct trade relationship enables the chocolate maker to have a greater say or more control in farming practices and post-harvest processing of cacao.

For us, tree to bar chocolate means the chocolate maker is also the farmer of the cacao used to make their chocolate. We farm our cacao and process the beans in Cameroon, then ship the dried beans to London where we turn them into different types of chocolate bars and chocolate spread. We own—and control—the entire journey of the cacao bean from tree to bar.

Because we are tree to bar, we’re also bean to bar. We could’ve contented ourselves with being bean to bar, but as mentioned above, our motivation is beyond just control of flavour development and product quality.

Difference between tree to bar chocolate and bean to bar chocolate

A tree to bar chocolate maker is automatically a bean to bar maker, but the two non-legal terms are not interchangeable.

As the name implies, bean to bar is when a chocolate maker produces chocolate from the dried cacao bean as opposed to a maker who uses already ground cacao bean called chocolate liquor or one who melts chocolate blocks into a brand’s desired shapes.

Elsewhere, we go into details on the big differences between tree to bar and bean to bar, but here’s a snapshot of those differences.

· Tree to bar chocolate maker controls the entire supply chain while the bean to bar maker only controls the processing stages from the dried beans.

· Tree to bar chocolate is usually single origin, but bean to bar may not necessarily be.

· Tree to bar maker can turn cacao byproducts into other useful cacao-originated products like Boocha, our cacao juice infused kombucha.

· The ease of traceability with tree to bar is almost automatic unlike bean to bar which may need serious record keeping of where the chocolate maker sources their dried beans.

· While tree to bar chocolate can ensure there’s effective sustainable farming practices, the bean to bar maker usually depends on third-party certifications schemes to know they’re sourcing ethically farmed beans.

The biggest difference between tree to bar and bean to bar is how much of the production chain the chocolate maker controls. The tree to bar maker controls 100% and the bean to bar controls just about 30%.

Tree to Bar vs. Direct Trade

Not every chocolate maker can become a cacao farmer and vice versa. But there are models that try to bridge the gap between chocolate maker and farmer that is usually widened by middlemen.

Direct trade chocolate makers source their beans directly from farmers or farmer cooperatives, usually Fair-Trade certified farms. This model cuts out the middleman of the mass market so the farmer can get a bigger income. Unfortunately, direct trade does not always translate into bigger incomes for farmers and farm workers because fair trade is not always fair.

LEARN MORE: What REALLY is Ethical Chocolate?

Direct trade chocolate makers are usually bean to bar makers. Tree to bar brands, being the owner of the farm, have farm workers they employ, and the cacao beans is usually for the sole use of the brand. This model has the shortest supply chain, making traceability easy-peasy.

Our process to make chocolate from tree to bar

Cacao farming takes time. A cacao tree takes about 3 years to start flowering and 5-6 months for the flower to become a ripe pod with cacao beans. During this stage, the cacao farmer has specific responsibilities to ensure a good crop.

First, the farmer chooses what varieties of cacao to cultivate and prepares the seedlings for planting in good soil. From the seedling to the mature tree, the farmer ensures the tree receives adequate nutrition and moisture, is shaded from direct sunlight, and that pests and harmful insects are kept away. This is laborious and expensive. The farmer usually employs farm workers to carry out the various tasks of caring for the trees.

We cultivate all the 3 main types of cacao varieties. Once their fruit is ripe, a sequence of stages sets in.

1. Harvest and post-harvest stages

i. Harvesting:

Using machetes, our farm workers carefully take off ripe pods from the trees and gather them into heaps. The pods are then cracked with the machetes to extract the pulp-covered beans.

ii. Fermentation:

The cacao bean needs to go through fermentation to begin the development of flavour. Fermentation also reduces the natural bitter, astringent flavour of the cacao bean. We pile the wet beans on banana leaves and cover to increase bean temperature and give bacteria and fungi time to feast on the sugars in the pulp. Effective cacao bean fermentation takes 4-6 days.

One advantage we have as tree to bar maker is the redemption of cacao pulp that should otherwise go to waste. Only 25% of cacao pulp is needed for bean fermentation, meaning 75% usually goes to waste. In our effort to add value to the supply chain and make it more profitable, we developed an exceptional blend of kombucha tea and cacao pulp juice as a byproduct of cacao production.

iii. Drying:

We spread fermented beans on mats to dry under the sun. Here, we cannot afford to rush or slacken the process because there will be consequences. Cacao bean needs to lose about 70-85% moisture during drying and the rest during storage for proper flavour development. Depending on the weather, we dry our beans for 7-10 days. Then we pack the dried beans into bags and store, ready for shipping to London where we make chocolate.

2. Chocolate making stages

This is where the bean to bar maker starts after getting dried beans.

iv. Roasting:

We clean dried beans of dirt picked during drying and roast them to release their irresistible chocolate flavour. And to kill microbes. Just like during the drying stage, we have to be careful to get it right. Too much heat or prolonged roasting would turn our chocolatey bean into a black crumb of bitter charcoal.

v. Breaking into nibs and winnowing:

The edible part of the cacao bean is covered in an inedible shell. Breaking separates the shell so it can be blown away in a winnower. What is left is cacao nibs ready for milling.

vi. Milling:

We grind the roasted cacao nibs in a miller to produce liquid called cacao liquor. This is pure cacao, in almost equal proportions of cacao butter and cacao solids. This stage is where many producers can begin adding other ingredients according to their chocolate formula or press out the butter, leaving a cake of cacao solids. We do not make cacao powder, so from here, we add other ingredients depending on the bars we make.

Some of our tree to bar chocolates. We have dark bars, a milk chocolate bar, and a blonde (toasted white) chocolate bar. Click here to see all.

vii. Tempering:

It’s not by accident that chocolate snaps when you break or bite it. Tempering is the alternate heating and cooling that gives your bar a shiny look and a snappy breaking sound.

viii. Moulding and packaging:

We now pour our tempered liquid chocolate into forms to harden and get ready for packaging.

Basically, that’s our tree to bar process. The fundamentals are pretty standard, adaptable to each chocolate maker.

But packaging, or even getting our chocolates to shops, isn’t our end goal.

We’re more than just a tree to bar chocolate brand: Why we do what we do

With control of the entire supply chain, we can tweak and modify our processing techniques to get variations in flavour and product offerings. That should satisfy our esteemed ethical customers, but that’s just part of why we do what we do.

Our founder Mbida Veronique first met cacao as a little girl visiting her grandmother. To her, the pulp was the most precious part of the cacao fruit. Even when she later tasted chocolate, it was just a mere treat. Until she learned about the social and economic injustices that plague the cocoa industry. Then she found a purpose and a new passion: to create a supply chain that’s ethical, sustainable, and fair to all stakeholders.

There’s much focus on the plight of African cocoa farmers, which is great, but not enough attention on the conditions of those employed to work on cocoa farms. If cacao farm owners are not able to earn a living income, farm workers fare even worse with unliveable wages.

LEARN MORE: How We Go Beyond Fair Trade to Provide Living Wages to Farm Workers

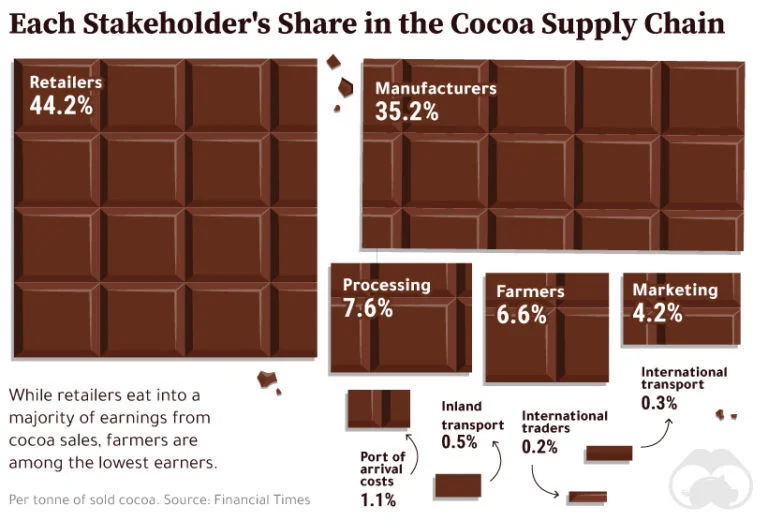

Chocolate is a 133.6-billion-dollar industry (2024, Statista). Manufacturers get 35% of that revenue, 44% goes to retailers, and a meagre 6.6% goes to cocoa farmers.

Courtesy World Economic Forum

Stats like these convince us that fair trade is a step in the right direction, but it’s not enough. The different levers of fair trade do not guarantee a living income for the cocoa farmer, not to talk of the cocoa farm worker who bears the brunt of the work of caring for the cacao tree until the dried beans are shipped to selling cooperatives.

We stepped in to make a difference. A drop in a mighty ocean, but one that demonstrates that the chocolate maker doesn’t have to get fat on the sweat of the cocoa farmer and farm worker who cannot afford basic needs. To be tree to bar chocolate makers doesn’t cut it for us. We’re change makers.

Our farm workers receive the Anker Living Wage that enables them to get decent housing, food, water, and other essential needs inline with many of the United Nations Sustainable Development Goals . Founded on fairness, we can make a profit without sacrificing the livelihoods of those who make it happen on our generational farm.

We care about the environment

We cannot talk about ethical tree to bar chocolate without the welfare of the environment. We have planted thousands of trees on our cacao farm, eco-friendly economic plants like banana, avocados, plantains, and other trees that promote and conserve biodiversity and soil health.

This is why we do not believe that the end-product, chocolate, is all that matters, not to the ethical consumer, not to the ethical chocolate maker. Every stakeholder in the supply chain, including the environment, must equitably benefit from the revenue of the final product.

Our farming community is not left out

Even though we’re tree to bar, we care about the wellbeing of people in our farming community. Children in the community benefit from back-to-school materials and money from us and we have plans to expand our charity efforts to other areas in the community.

Benefits of Tree to Bar Chocolate: Model and Product

Going by our approach, tree to bar chocolate has several benefits, for the farm worker, the chocolate maker, and the chocolate consumer.

· Effective oversight of the supply chain

There’s effective oversight of the supply chain as opposed to other models like direct trade, bean to bar, or worst of all, mass chocolate.

· Elevating the dignity of the cocoa farm worker

Knowing farm workers, seeing their input, and appreciating it is part of contributing to achieving the sustainable development goals of elevating the dignity of work and self-esteem of the worker.

· The chocolate maker has control over flavour development from pre-processing stages

Soil, farming conditions, and type of cacao variety all contribute to the nuances of the final chocolate flavour. By owning the farm and controlling post-harvest and processing stages, tree to bar chocolate makers have the advantage of developing techniques to get unique flavours.

· Ethical consumers get a guilt-free indulgence

Tree to bar chocolate gives ethical consumers a clean conscience knowing their pound or dollar is going to support better conditions for the cocoa farm worker and sustainable farming practices.

· Tree to bar chocolate offers the benefits of single-origin chocolate

Chocolate does not have one flavour, not only because of the different varieties and subvarieties. Origin has its own influence on final flavour. Soil type, harvest, fermentation and drying techniques, along with production processes contribute to defining the flavour of the chocolate you get. Tree to bar chocolate is single origin chocolate, even when the chocolate maker has farms in different countries. There’s no blend of cocoa beans as found in mass-produced chocolate. Another big benefit of single origin chocolate is the highlight on origin country of the cacao beans, not just the country where the bean becomes chocolate. We’re proud to say our cacao comes from Cameroon, West Africa.

Where to buy tree to bar chocolate

You can buy tree to bar chocolates at retailers, the manufacturer’s physical shop, or online store. Bantu Chocolate crafts 5 different tree to bar chocolates at varying percentages of cacao of dark bars, a milk chocolate bar, and a blond chocolate (toasted white chocolate). We ship all over the UK, US, and Canada.

TAKE A LOOK AT OUR TREE TO BAR CHOCOLATES.

References

https://www.weforum.org/agenda/2020/11/cocoa-chocolate-supply-chain-business-bar-africa-exports/

https://stonehill.vn/what-is-tree-to-bar/

Chocolate Extinction: Fact vs. Fiction + What Chocolate Lovers Can Do

Chocolate ExtinctionFact vs. Fiction, What Consumers Can Do Share On Facebook Twitter Email Is the world really running out of chocolate? Not really. Currently the global […]

Corporate Chocolate Gifting Ideas to Appreciate Employees and Delight Clients

Corporate Chocolate GiftingHow to Appreciate Employees & Delight Clients Share On Facebook Twitter Email When it comes to corporate gifting, a one-gift-fits-all approach just doesn't cut […]

Cacao Supper Club at Home: Guide to Tasting Chocolate, Cacao Tea, and Pulp Juice

Cacao Supper Club at HomeGuide to Tasting Chocolate, Cacao Tea, and Pulp Juice Share On Facebook Twitter Email Imagine gathering around the table with a few […]